Key Differences Between Flash Freezing and Traditional Methods

Freezing Speed and Ice Crystal Formation

Flash freezing is a method where food is subjected to extremely low temperatures, typically below -30°C. This rapid freezing process leads to the formation of smaller ice crystals compared to traditional freezing methods. In traditional freezing, the slower temperature decrease results in larger ice crystals that can rupture cell walls, negatively impacting the food's quality. Studies indicate that the smaller ice crystals formed during flash freezing preserve the cellular structure, retaining texture and preventing mushiness in foods like meats. Consequently, flash-freezing offers a significant advantage over conventional methods by maintaining the integrity and appeal of food items.

Impact on Food Texture and Nutrient Retention

Flash freezing excels in retaining the moisture and flavor of food, leading to superior texture upon thawing. Traditional freezing often results in water loss, compromising texture. Research supports that nutrient retention is generally higher in flash-frozen foods, as the process better maintains vitamins and minerals compared to traditional freezing. This method is particularly beneficial for delicate products such as fruits and seafood, where preserving taste and texture is critical. By minimizing nutrient degradation, flash freezing ensures that the nutritional value of food is maintained, making it a preferred choice for preserving high-quality products.

Energy Efficiency and Operational Costs

Flash freezing is more energy-efficient than traditional methods because it reduces freezing time and utilizes optimized cooling technologies. Businesses that invest in advanced freezing systems can benefit from lower operational costs over the long term, especially through reduced energy consumption. Statistics reveal that integrating modern flash-freezing technologies can lead to a significant decrease in electricity expenses, positioning it as a sustainable option for food service operations. By lowering energy usage, companies not only cut costs but also contribute positively to environmental sustainability, making flash freezing a smart choice for both economic and ecological reasons.

Benefits of Modern Flash Freezing Technology

Reduced Drip Loss and Improved Shelf Life

Modern flash freezing methods significantly reduce drip loss and improve shelf life. Drip loss, the moisture released during thawing, is minimized using flash freezing, helping to preserve both the quality and weight of food over time. Compared to traditional freezing techniques, flash-frozen foods maintain their quality for extended periods, with industry reports indicating possible shelf life extensions of up to 60%. This improvement can greatly benefit food manufacturers and retailers by reducing spoilage and waste, making flash freezing a desirable choice for maintaining food quality.

Versatility Across Food Categories

Flash freezing technology is highly versatile, accommodating a wide spectrum of food types such as meats, fruits, vegetables, and prepared meals. Its widespread application across the food industry simplifies inventory management and reduces waste, making it an optimal choice for restaurants and food processors. This technology supports culinary innovation by enabling food brands to ensure consistent quality across diverse product lines, from plant-based alternatives to premium seafood. Major food brands have adopted flash freezing to enhance their product quality, catering to various consumer preferences efficiently.

Commercial-Grade Hygiene Standards

Adhering to strict hygiene standards, modern flash freezing equipment plays a pivotal role in reducing contamination risks during the freezing process. Automated systems incorporated in these freezing technologies streamline sanitation protocols, enhancing food safety significantly. Findings from food safety authorities underscore the importance of maintaining high hygiene standards in food processing. Flash freezing complies with these standards and is aligned with best practices, ensuring that the food reaches consumers in the safest possible condition. This aspect of flash freezing technology is crucial in maintaining compliance with industry regulations and consumer expectations for food safety.

Industrial Applications of Advanced Freezing Systems

Retail Ice Storage Solutions

Advanced freezing systems play a crucial role in providing retail outlets with efficient ice storage solutions, ensuring product quality and enhancing customer satisfaction. The rising demand for bagged ice has prompted innovations in ice storage, with flash freezing being a prominent technology used to achieve superior quality. This not only enables retailers to meet consumer demands but also allows for reduced maintenance and operational costs, resulting in a more efficient retail operation. By adopting these advanced systems, retailers can enhance their service delivery, thereby maintaining customer loyalty and satisfaction.

High-Volume Food Processing

Flash freezing is a critical component in high-volume food processing, as it allows for rapid freezing that aligns with the demands of large-scale production. This method optimizes processing times, enabling companies to increase their throughput while preserving food safety and quality. According to statistical insights, implementing flash freezing in food processing can result in productivity gains of up to 30%. Such an increase not only boosts the efficiency of food manufacturers but also ensures that they consistently deliver products that meet high-quality standards.

Outdoor Event Catering Needs

For outdoor events, having reliable freezing solutions is vital to maintaining food quality until the point of consumption, and flash freezing meets this requirement effectively. Flash-frozen foods can endure long transportation periods and storage times without the risk of spoilage, ensuring that caterers can deliver fresh, high-quality meals. This capability offers increased adaptability to caterers, allowing them to cater to various event conditions while enhancing their service offerings—ultimately leading to a better customer experience during these events.

Commercial-Grade Freezing Equipment for Optimal Preservation

Slant-Door Cube Ice Freezer with Cold Wall Technology

This commercial-grade ice freezer incorporates cold wall technology, delivering superior temperature consistency to enhance ice quality. The advanced cooling mechanism ensures uniform low temperatures by minimizing direct airflow, substantially reducing energy consumption. This aligns well with modern sustainability goals, promoting energy-efficient solutions in commercial settings. Additionally, the consistent cooling provides faster and easier access to high-quality ice, thereby increasing user satisfaction and enhancing operational efficiency.

Weatherproof Outdoor Ice Storage Cabinet

The weatherproof design of the outdoor ice storage cabinet ensures that ice remains fresh and ready for customer use, even in challenging conditions. This cabinet is crafted to withstand harsh environments, which not only extends the equipment's lifespan but also minimizes maintenance, offering significant cost efficiency over time. Ideal for settings that necessitate ice storage away from direct sunlight, its robust construction means less ice melt and a consistently high-quality product.

High-Capacity Bagged Ice Dispenser System

High-capacity bagged ice dispensers significantly streamline operations where large volumes of ice are needed, ensuring rapid service delivery. These systems are essential in reducing manual ice handling, thereby minimizing contamination risks and enhancing hygiene. In busy environments such as restaurants and event venues, the efficiency of these dispensers can lead to increased sales by facilitating faster service and improving customer satisfaction.

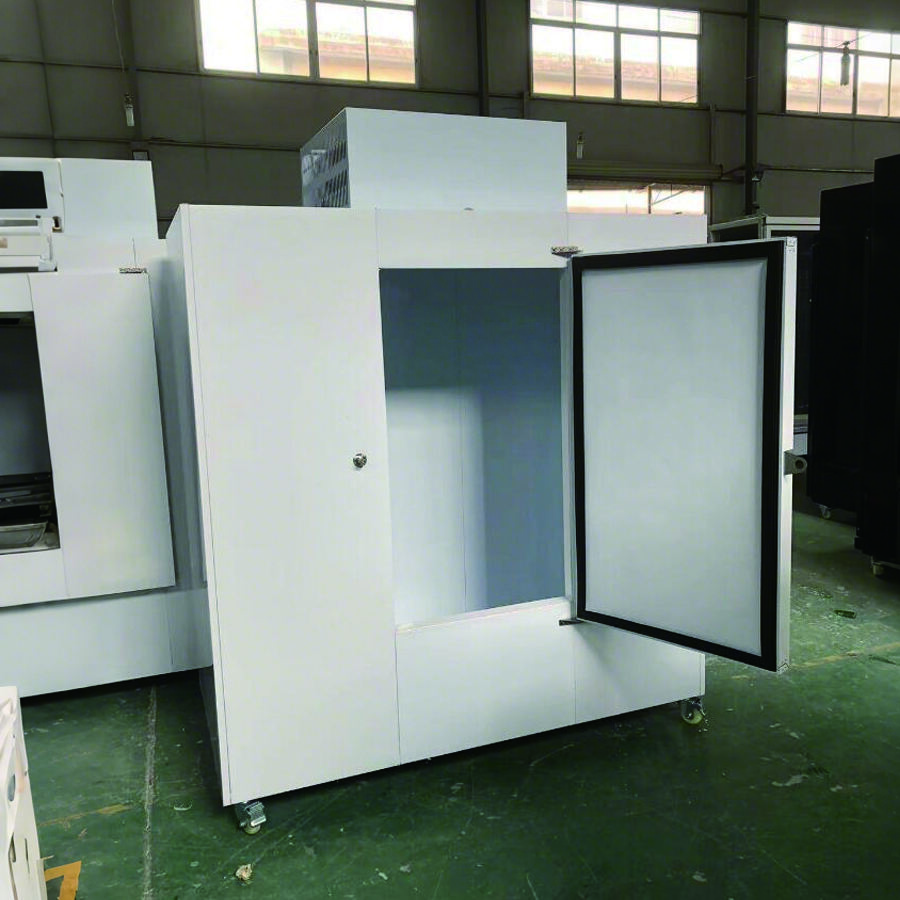

Double-Door Merchandising Freezer for Bulk Storage

The double-door merchandising freezer is designed for optimal visibility and accessibility, crucial for businesses aiming to attract customer attention. Its energy-efficient design ensures reduced electricity costs while maintaining ideal storage conditions, making it a cost-effective solution for retailers. Moreover, the strategic display options of this freezer serve to highlight products effectively, enhancing merchandising efforts and potentially boosting sales.

Future Trends in Food Preservation Technology

AI-Enhanced Temperature Control Systems

AI technology is poised to revolutionize food preservation with advanced temperature control systems. These systems have the capability to monitor and adjust storage conditions in real time, ensuring optimal preservation of food quality and safety. By accurately predicting and preventing temperature fluctuations, AI enhances the reliability of freezing methods. Industry experts suggest these AI-enhanced operations could reduce food waste by up to 20%, reflecting a significant improvement in efficiency (source: Food Engineering). As the food industry increasingly integrates sophisticated technologies, AI-driven solutions are set to play a critical role in extending the shelf life of frozen products.

Sustainable Freezing Practices

Sustainability in freezing practices is gaining traction as the food industry leans toward eco-friendly operations. New technologies are incorporating renewable energy sources, significantly reducing the carbon footprint associated with traditional freezing methods. According to various environmental agencies, these sustainable practices may soon become regulatory standards within the industry. By utilizing such eco-friendly technologies, companies not only contribute to environmental conservation but also align with consumer expectations for responsible manufacturing processes. As this trend grows, the food industry is expected to innovate further to comply with these emerging environmental standards.

Customizable Branding Integration

Customizable branding in freezing equipment presents a unique opportunity for companies to boost their market presence and recognition. By integrating branding elements into storage solutions, businesses can create memorable interactions with customers, particularly in retail environments. According to emerging trend surveys, companies employing such strategies have reported an increase in customer loyalty. This approach not only strengthens a brand's image but also provides a platform for engaging consumers with tailored experiences. As the demand for personalized marketing grows, customizable branding in freezing equipment is set to become a pivotal strategy in retail and food service industries.