Understanding Blast Freezer Fundamentals

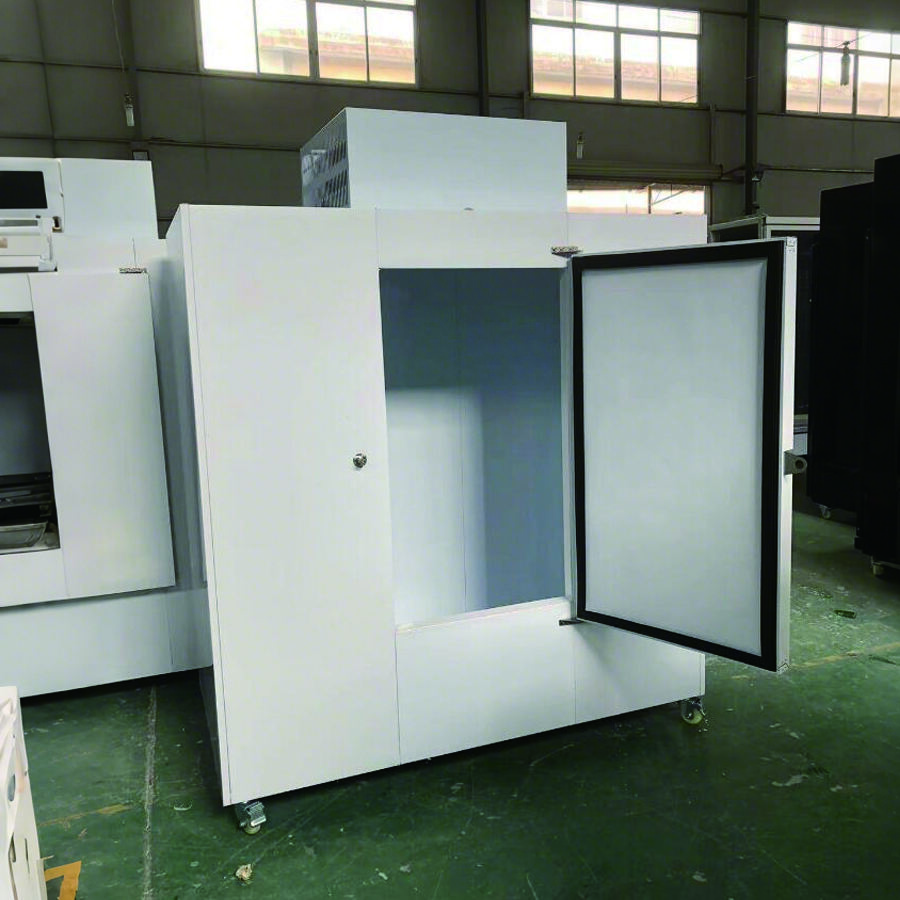

How Blast Freezers Work Differently from Standard Freezers

Blast freezers operate using advanced refrigeration technology that rapidly cools products at temperatures typically at -18°C (0°F) or lower. Unlike standard freezers that may operate at higher temperatures, this quick freezing process is crucial for preserving the food’s cellular structure. The main mechanism involves forced air circulation, creating a more consistent cooling environment compared to standard freezers that rely on static cold air. This method significantly reduces the formation of ice crystals within the food, thereby preserving its texture and quality.

Temperature Ranges and Freezing Speed Explained

Blast freezers can achieve freezing temperatures much quicker than conventional freezers, often reaching full freeze status in under 3 hours. This rapid freezing is vital for maintaining food quality, particularly for items such as fish and meats, where preserving texture and integrity is crucial. The quick freezing capability not only keeps the food safe from bacterial growth but also ensures that its freshness and nutrients are retained effectively. This makes blast freezers particularly beneficial for commercial uses, such as preserving seafood and maintaining the quality of cold room freezer fruit.

- Within 3 hours, blast freezers can freeze completely.

- Essential for items like fish and meats to preserve quality.

- Ensures food safety by preventing bacterial growth and maintaining nutrient retention.

Explore more on small blast freezer for sale and factory blast freezer for fish cold room options to cater to specific preservation needs.

Key Benefits of Blast Freezers in Food Preservation

Preventing Bacterial Growth & Extending Shelf Life

Blast freezers play a crucial role in food preservation by rapidly reducing temperatures, thereby inhibiting bacterial growth and significantly extending the shelf life of perishable goods. Studies have indicated that products stored in blast freezers can have up to 50% longer shelf stability compared to traditional freezing methods. The rapid cooling process creates an environment where bacteria cannot thrive, ensuring food safety over a prolonged period. Additionally, the swift freezing technique minimizes nutrient loss, preserving the quality of the food for safe consumption.

Preserving Texture and Nutritional Integrity

Blast freezers excel in maintaining the texture and nutritional integrity of food products. The rapid freezing process locks in moisture and flavor, preventing the soggy texture often associated with slower freezing methods. This quick freeze prevents the formation of large ice crystals that typically damage cellular structures, thus preserving vitamins and minerals more effectively. Foods like fish and meats retain their original characteristics, making blast freezers essential for industries requiring high-quality preservation. This technology ensures that the food's nutritional benefits are upheld, meeting consumer demands for fresh and high-quality products.

Best Practices for Blast Freezer Operation

Loading Techniques for Optimal Airflow

Ensuring optimal airflow is a crucial factor for achieving uniform freezing in blast freezers. To enhance airflow, it is essential to properly space products within the freezer. This spacing allows cold air to circulate freely, ensuring that products are evenly frozen. Overloading the blast freezer can significantly hinder its performance. By blocking air circulation, overloading can lead to uneven temperatures, thus compromising food safety and quality. Proper loading techniques not only maintain freezing performance but also ensure that foods are preserved effectively without the risk of spoilage.

Maintenance Protocols for Peak Performance

Regular maintenance is vital to ensure that blast freezers operate at peak performance. Key maintenance tasks include checking refrigerant levels and cleaning condenser coils. Both of these actions contribute to the efficient operation of the unit, ensuring it maintains the necessary temperatures for freezing. Establishing a routine maintenance schedule is also crucial; it helps prevent unexpected breakdowns and ensures that the freezer retains its optimal freezing speeds. Consistent performance ensures that food safety standards are consistently met, safeguarding the quality and longevity of frozen products.

Food Preparation Guidelines Pre-Freezing

Proper food preparation prior to freezing is essential for optimal results. One crucial guideline is to cool cooked items to room temperature before placing them into the blast freezer. This prevents the sudden introduction of warm food from compromising other frozen goods within the unit. Another effective technique is vacuum sealing, which enhances preservation by reducing exposure to air, thereby ensuring ingredients maintain their integrity over time. Such preparatory measures contribute significantly to maintaining the quality and extending the shelf life of frozen products.

Commercial Ice Storage Solutions for Foodservice

30cuft Ice Merchandiser Cabinet with Cold Wall Technology

The 30cuft Ice Merchandiser Cabinet is a smart solution for ice storage, employing cutting-edge cold wall technology to sustain ice at optimal temperatures, minimizing melt. This technology ensures even cooling without direct airflow, which reduces ice sublimation—a common concern in high traffic areas. Perfectly suited for foodservice operations, this cabinet effectively combines storage with accessibility, facilitating seamless access and display. Whether in supermarkets or convenience stores, its versatility and efficient design make it indispensable for businesses that require consistent ice availability.

Slant-Door 38cuft Freezer Box for High-Capacity Needs

The slant-door 38cuft freezer box is designed to meet the demands of top-tier restaurants and catering services requiring substantial frozen product capacity. Its structure supports bulk storage, catering to high-volume needs. Notably energy-efficient, this freezer box utilizes cold wall technology and robust materials to deliver reliable performance while promoting long-term cost savings. It is ideal for commercial kitchens looking for a blend of capacity and efficiency, enabling consistent operation without compromising quality or increasing overhead costs.

Outdoor -18°C Storage Cabinet for 125 Ice Bags

Designed for outdoor applications, the -18°C storage cabinet offers stable and effective long-term ice storage. Maintaining a precise temperature, this cabinet can accommodate up to 125 ice bags, making it ideal for outdoor events or venues with high demand. Its robust construction resists weather elements, ensuring reliability and maintaining temperature control. This cabinet guarantees consistent ice supply for events like festivals and farmers' markets, seamlessly integrating into high-traffic areas without performance compromises.

Windproof 65cuft Dispenser-Freezer for Retail Use

The 65cuft dispenser-freezer is specifically engineered for retail use, featuring windproof capabilities to preserve ice quality under challenging conditions. Its design allows for effortless ice dispensing, fulfilling consumer needs while maintaining an attractive presentation. With its robust structure and efficient cooling technology, businesses can confidently stock and showcase ice, optimizing customer satisfaction and operational efficiency in environments like gas stations and beach kiosks.

Selecting the Right Blast Freezer for Your Operation

Capacity Planning Based on Service Volume

Determining the correct capacity for a blast freezer is essential for efficient operations and reduced wait times. When selecting a blast freezer, consider your peak service volume to ensure it can handle your busiest periods. A general guideline suggests that one cubic foot can accommodate approximately 28 pounds of product. This measurement is critical in estimating the appropriate freezer size to meet your specific needs. Effective capacity planning not only enhances service efficiency but also ensures you make the most of your investment by minimizing waste and optimizing storage factory blast freezer for fish cold room. By accurately assessing your operational requirements, you can select a blast freezer that aligns with your service demands.

Energy Efficiency vs. Freezing Power Tradeoffs

In the realm of blast freezers, there is often a tradeoff between energy efficiency and freezing power. While more powerful blast freezers provide rapid freezing capabilities beneficial for preserving product quality, they usually entail higher energy costs. This increase can significantly impact overall operational expenses. It is crucial to find a balance between energy consumption and the necessary freezing power for your operation. Consulting with an energy efficiency expert can provide valuable insights into optimizing this balance for your specific needs. This expertise can help tailor a solution that manages energy use while achieving the desired freezing performance commercial deep freezer containers. Making informed choices in this area can lead to long-term savings and enhance the sustainability of your operation.